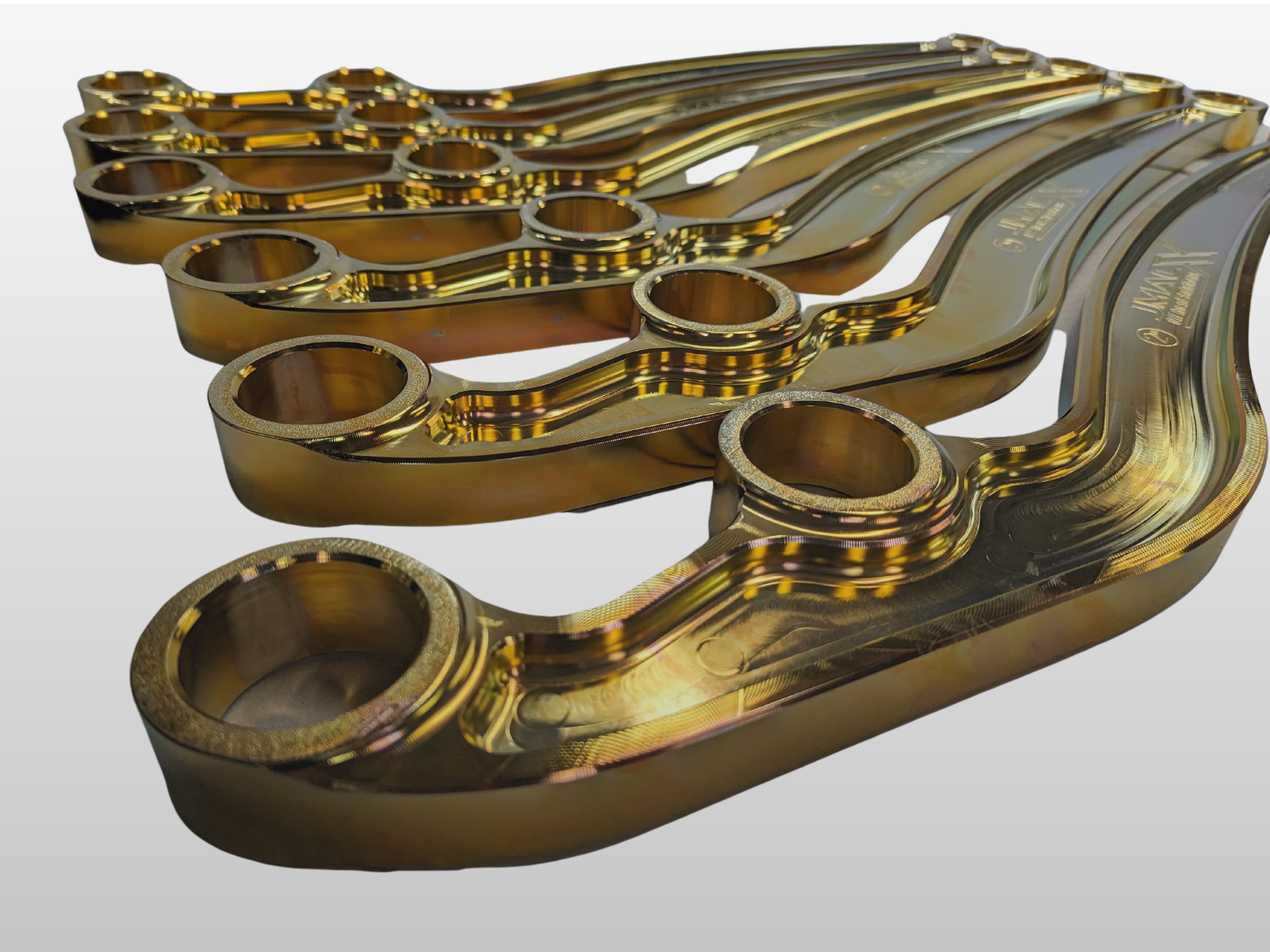

Cobalt Plating (CB)

We excel in Cobalt Plating, delivering superior wear resistance for critical components in various industries

CB

Cobalt Plating (Cb) Blue / Silver & Gold (SA5)

Cobalt plating is a specialized electroplating process that enhances metal substrates’ surface properties and performance. Immersed in an electrolyte solution containing cobalt ions, the substrate undergoes deposition facilitated by an electric current. Renowned for its exceptional wear resistance and hardness, the durable cobalt layer acts as a protective barrier, making it ideal for components exposed to abrasive environments, heavy loads, or high-friction conditions. Extensively used in aerospace, oil and gas, automotive, and electronics industries, cobalt plating ensures critical components’ longevity and reliability, effortlessly withstanding demanding operational challenges.

At Australian Plating Services, we pride ourselves on our capability to accommodate plating projects of various sizes and complexities, including parts up to impressive dimensions of 1500mm x 450mm x 900mm. Supporting single Plating pieces up to an impressive 500Kg. Our state-of-the-art plating facilities and specialized equipment enable us to handle large-scale components with ease, while still maintaining the same level of precision and attention to detail.

F.A.Q.

Here are five frequently asked questions (FAQs) about Cobalt Plating

What is Cobalt Plating?

Cobalt Plating is a specialized electroplating process that deposits a layer of cobalt onto metal substrates, enhancing their surface properties and performance. The plated cobalt layer provides exceptional wear resistance and hardness, making it ideal for components subjected to abrasive environments or high-friction conditions.

What are the benefits of Cobalt Plating?

Cobalt Plating offers remarkable benefits, including superior wear resistance, increased hardness, and enhanced durability. The plated cobalt layer forms a protective barrier, making it highly suitable for components exposed to harsh conditions, such as those found in the aerospace, oil and gas, automotive, and electronics industries.

What industries commonly use Cobalt Plating?

Cobalt Plating finds extensive application in industries such as aerospace, oil and gas, automotive, electronics, and more, where components require exceptional wear resistance and protection from abrasive or high-friction environments.

Can Cobalt Plating be applied to various substrates?

Yes, Cobalt Plating can be applied to a wide range of metal substrates, including steel, iron, copper, and other alloys. Its versatility allows it to enhance the performance of components made from various materials.

How thick is the Cobalt Plating coating?

The thickness of the Cobalt Plating coating can be adjusted based on the application’s needs and requirements. Typically, it ranges from a few microns to several tens of microns, ensuring adequate wear resistance while maintaining the desired dimensional tolerances.

Benefits of this Process

- Superior Wear Resistance

- High Hardness

- Low Friction

- Chemical Stability

- Uniform Coverage

- Heat Resistance

- Enhanced Electrical Conductivity

- Adhesion Promotion

- Dimensional Stability

- Versatile Applications

Call For a Quote:

(346) 234-6973

Related Services

Electroless Nickel Plating

Specialising in Brass & Steel

Zinc Plating

Zinc Plating (Zn) Blue / Silver & Gold